Rotary Seals Bring Sweet Success to the Chocolate Industry

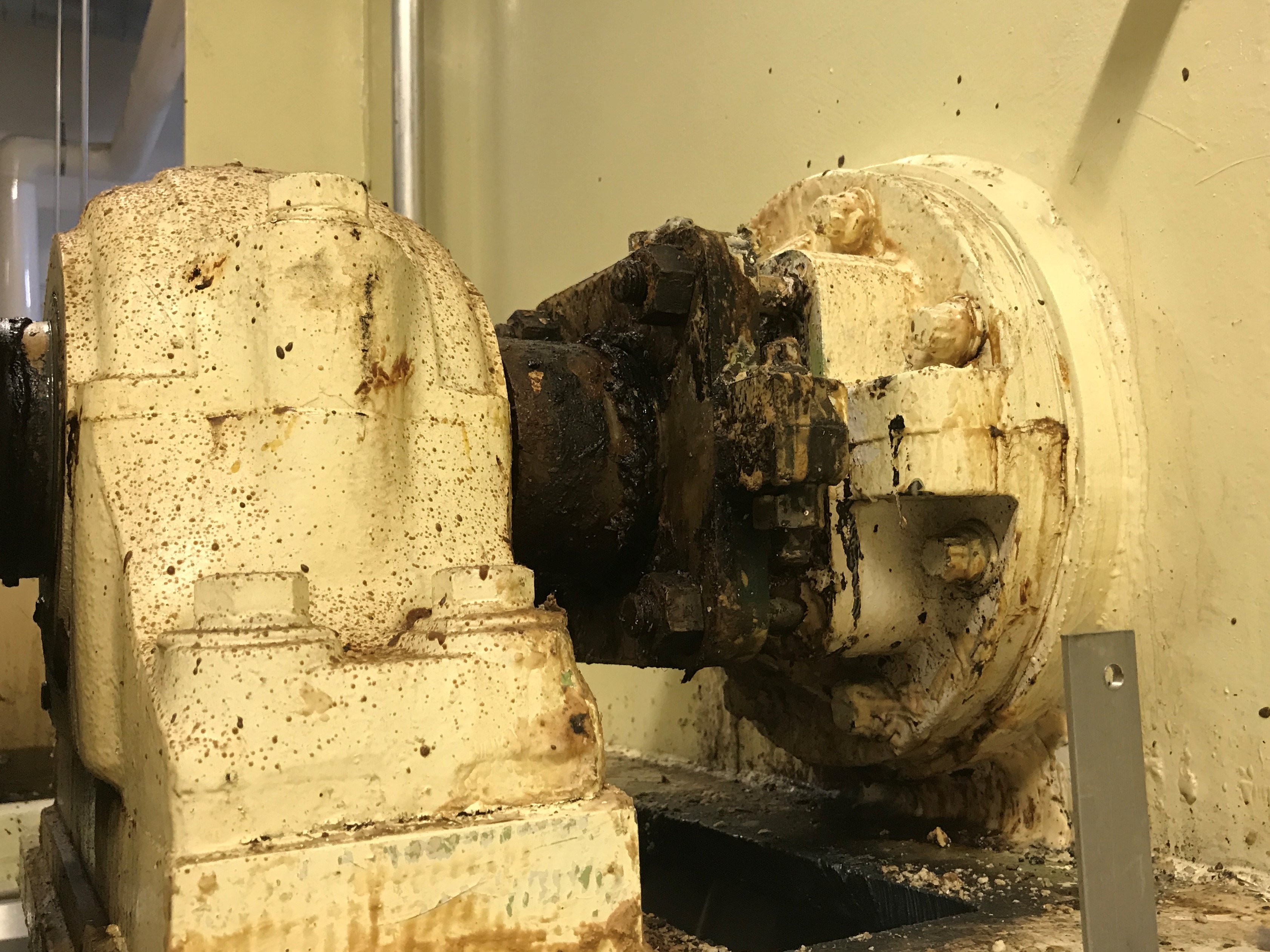

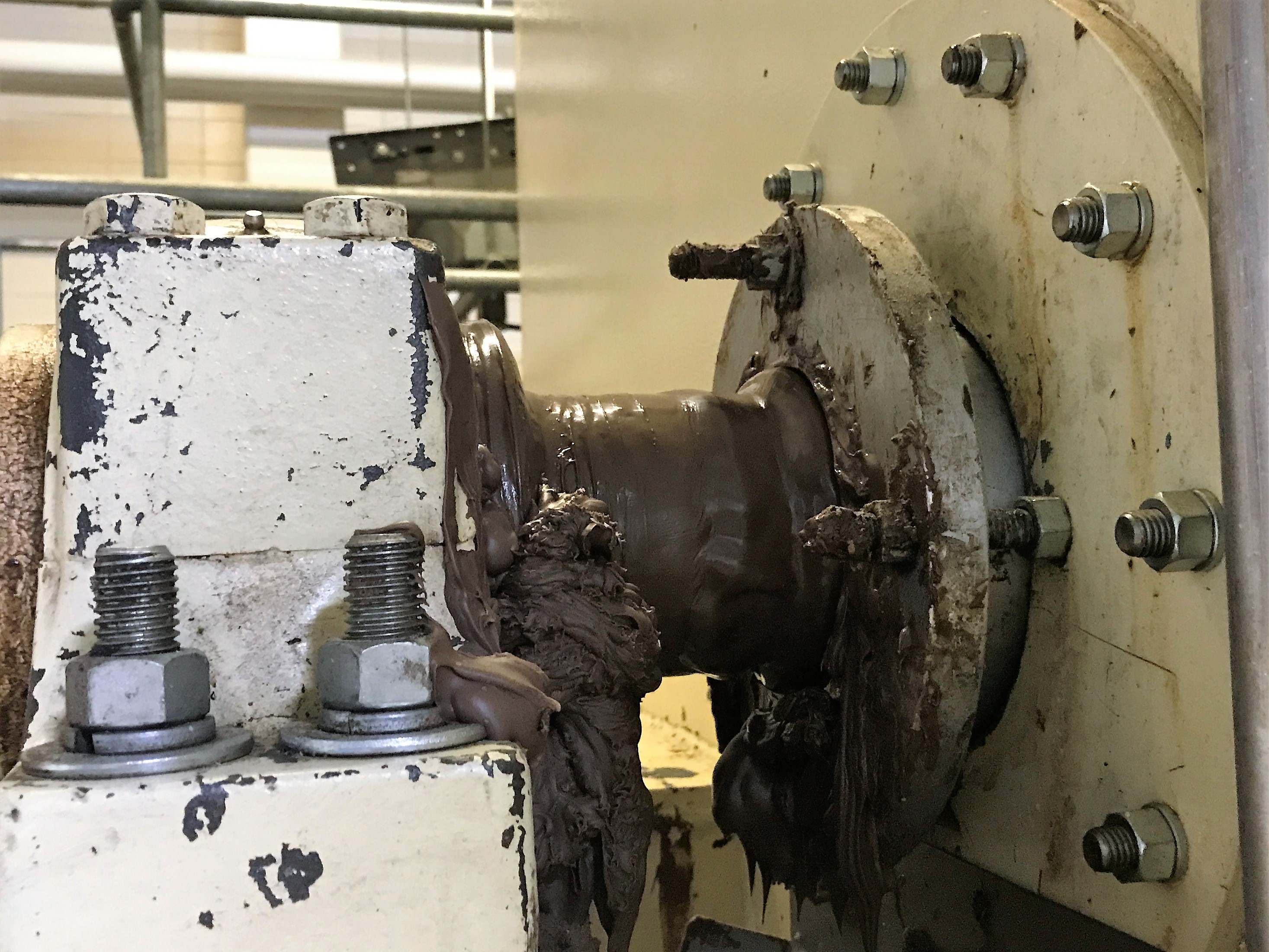

Rotary shaft seals for chocolate manufacturing equipment solve the issue of product leakage in industrial mixers, blenders, and more. Other sealing technologies like mechanical and lip seals can result in costly chocolate leakage and downtime for repairs and maintenance. Rotary shaft seals, on the other hand, prevent these issues at the source.

Making the switch to rotary seals by CinchSeal is a great way to protect chocolate holding tanks, melting tanks, conches, cocoa refiners, sugar screw conveyors, and mixing equipment.

CinchSeal Chocolate Solution

For 25 years, CinchSeal has been a global leader in manufacturing innovative rotary shaft seals that provide complete bearing and

shaft protection on screw conveyors, ribbon blenders, mixers, and all types of food and bulk-processing equipment. In harsh chocolate environments, CinchSeal products make the need for processing equipment replacement far less likely as they solve problems associated with traditional lip seals and mechanical packing: prevent bearing failure, shaft damage, chocolate leakage and loss, contamination, frequent cleaning, and unscheduled downtime.

CinchSeal’s customers include Fortune 100 companies that have installed standard CEMA and custom-engineered rotary shaft seals on Chocolate Holding Tanks, Melting Tanks, Conches, Cocoa Refiners, Sugar Screw Conveyors, and Mixing Equipment.

- Prevent product leaks, frequent repairs, and unscheduled downtime

- Protect bearings and shafts from failure and damage and stop product loss due to leakage

- Take advantage of the split seal design and spend less time cleaning – without the need to take apart your processing equipment

- Keep your employees productive and operations running efficiently and smoothly

- Prevent cross-contamination, foreign material migration, and product recalls

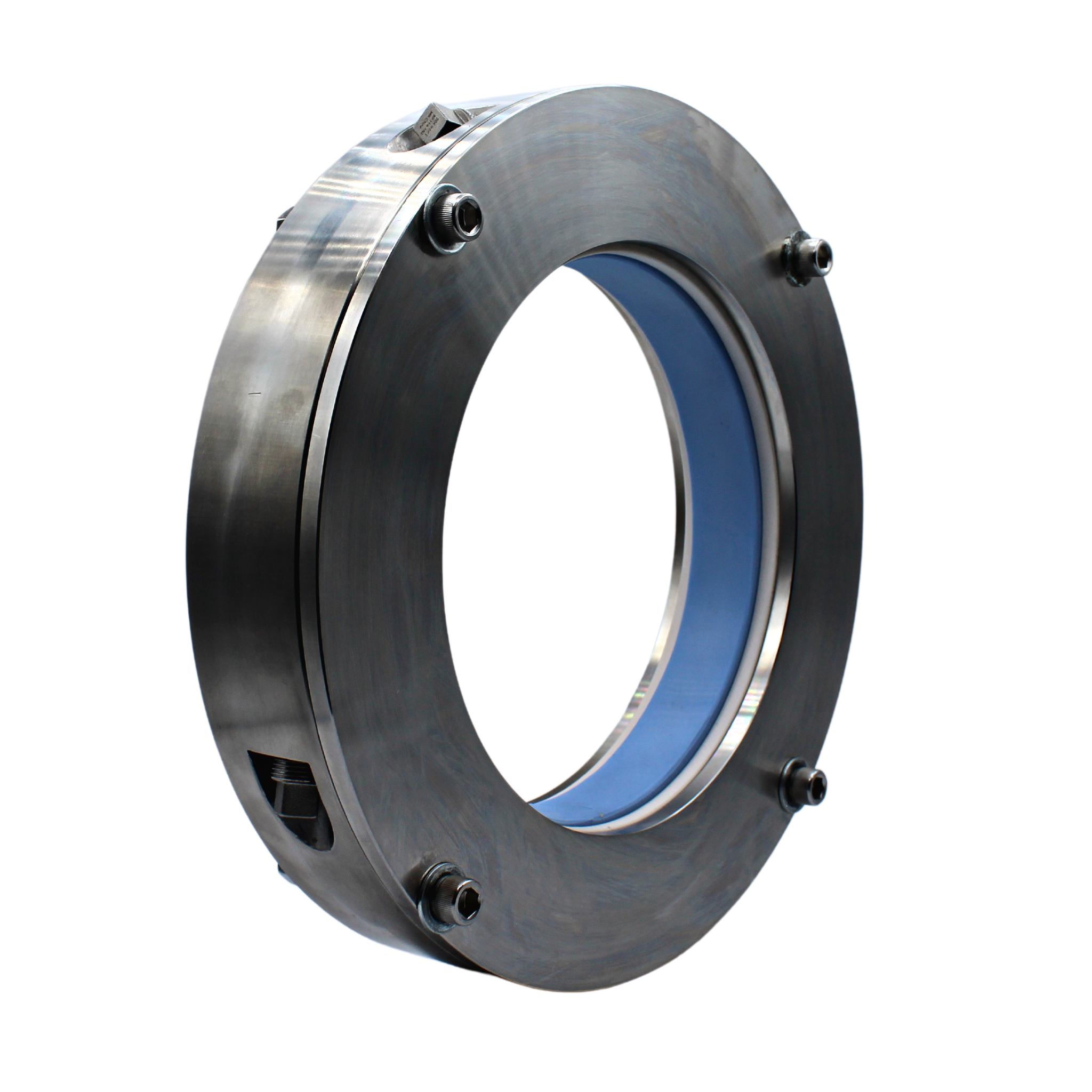

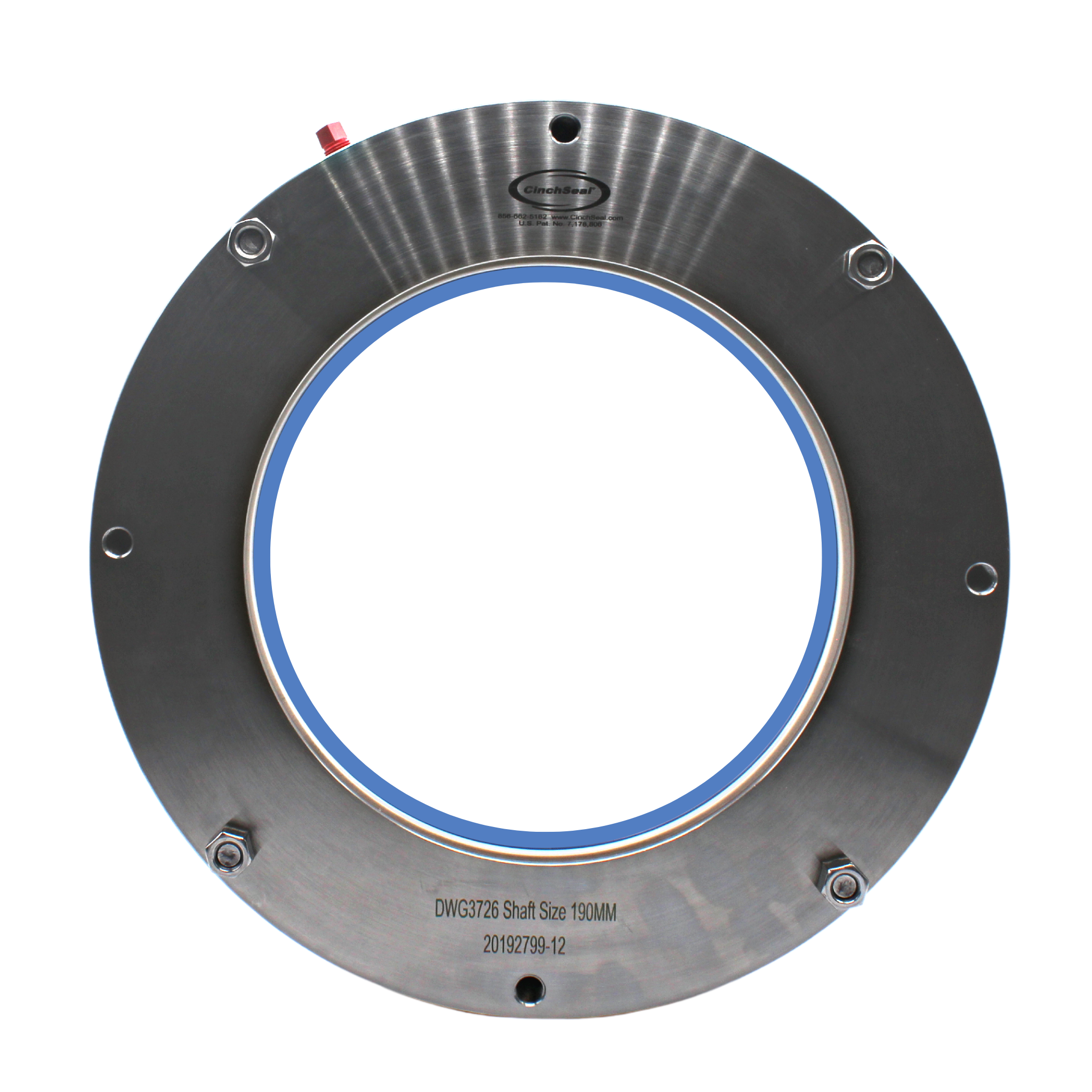

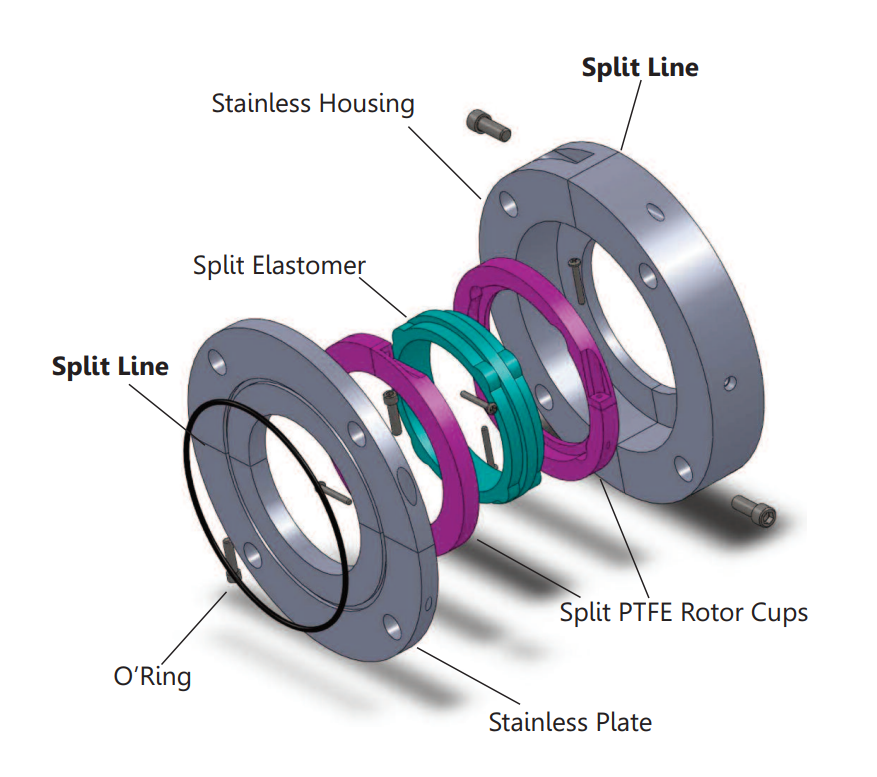

Split 9700 Series Mixer Rotary Shaft Seal

The 9700 series hygienic rotary shaft seal for industrial mixers and blenders is machined out of stainless steel, and all internal parts meet FDA standards for indirect food contact.

- Can be easily disassembled for batch or weekly cleaning

- rebuild kits available for sanitation requirements

- All-metal design gives many years of reliable and continuous service

How the 9700 Works

The heart of the 9700 CinchSeal is the FDA approved elastomer which is designed to create an interference fit on the shaft. This tight fit allows the elastomer to turn with the shaft and thereby eliminating shaft damage or wear. The elastomer seals the shaft and stops product from migrating past while also turning a set of mineral filled PTFE rotor cups. As the elastomer and rotor cups turn with the shaft they are compressed with the optimum amount of face pressure against a stationary face. The rotating face against a stationary face is what creates the primary seal that stops product from getting by. The PTFE rotor cups are designed to be the wearable part of the seal and repair kits are available. The repair kit consists of two new PTFE split rotor cups and new split elastomer. The seal is designed to be purged with air 5 to 8 PSI over vessel pressure to keep rotating seal faces cool and free of material. The 9700 seal is easy to take apart, clean, and re-assemble for daily maintenance.

Documents

CinchSeal Chocolate Solution Overview

Product Overview - 7520 Rotary Shaft Seal - Screw Conveyors

Product Overview - 7550 Rotary Shaft Seal - Screw Conveyors

Product Overview - 7620 Rotary Shaft Seal - Large Shaft Diameter

Product Overview - 7650 Rotary Shaft Seal - Large Shaft Diameter

Product Overview - 7850 Rotary Shaft Seal - Sanitary Food Processing